Top 5 Most Common Occupational Hazards

Our surroundings are filled with many hazards, especially at our workplaces there might be tens of occupational hazards, which if unchecked, can be the cause of a disaster or a loss of human life or an important asset. Everyday work involves many procedures, some of which might require tackling difficult situations like machine work, transporting chemicals, maintaining electrical equipment or working in extreme conditions like heights, hot zones and confined spaces.

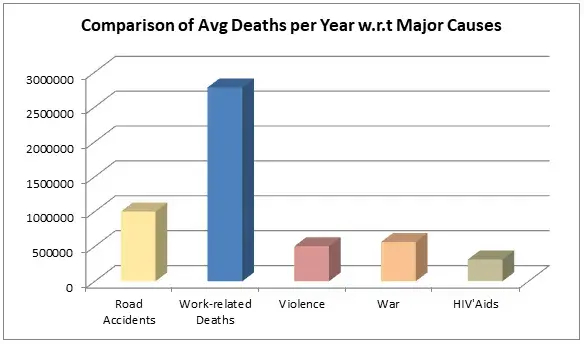

As per United Nation’s ILO (International Labor Organization), approximately more than 2 million people die each year due to work-related causes; a number that exceeds the average annual deaths from violence, war, HIV/Aids and road accidents. Worker’s health & safety is always important to get the job done accurately in a timely manner and it’s not only the supervisor’s duty to maintain health & safety standards, but also the higher management to implement effective health & safety frameworks to prevent losses. The workforce shall also be given appropriate health and safety trainings on timely basis to keep them updated of accurate working procedures to establish safe work practices and to minimize the risk of losses & accidents.

Comparison 1: Statistics from UN Global Compact

Here are the most common top 5 occupational hazards with relevant examples for better understanding on how to avoid them.

Working at Heights:

Big or small, heights are always hazardous for workforce, if proper safety measures are not taken. Whether it’s a simple paint job or fixing a telecom tower or working on a cradle or any high altitude technical job, proper use of equipment like safety harness, helmet, safety boots and efficient use of relevant tools make the job done safely.

To understand better, let’s take an example of the most common work on height which is cradle operations. Suspended Platform Cradles are used for multiple reasons, mostly for building maintenance, but shall always be checked if it’s properly functioning before putting into work. Also, there are few other important things to be taken into consideration to ensure safe cradle operations, like

- Calm weather conditions shall be ensured, because if there started raining or strong winds during the work, it can make the Gondola Cradle unstable causing accident and losses.

- The total weight on the cradle shall not exceed the Safe Work Load Limit.

- Cradle is installed properly by competent professionals as per the manual for safe and an appropriate rescue from heights plan shall also be ensured before working.

- Workers on the cradle shall be duly trained for height safety and on how to accurately & safely work on Gondola Cradle before working.

- Ensure that the safety lanyard of worker’s harness is always connected with the anchorage point to avoid falls and other accidents.

- In case of malfunctioning, the cradle shall be stopped and reported at once instead of taking chances.

- While, the cradle is in working, no other work shall be conducted above or below it and the area below the cradle shall be properly barricaded to avoid causing accidents for people other than workers also.

Other similar high altitude jobs shall only be taken after work at height safety awareness which provides comprehensive understanding of risks associated with working at heights and safety strategies to ensure accurate implementation of height safety rules preventing fall injuries, accidents and life-long traumas.

Unstable / Inappropriate Structures:

Whether you are at home trying to fix a bulb on a chandelier or at Scaffolding in a construction site for a building repair & maintenance, stable installation of the ladder or scaffolding ensures worker’s safety and to avoid falling objects. Likewise, there are other jobs including Roofers, Construction Laborers, Building Painters, Electricians, window fixers & cleaners who might be using scaffolds or ladders to do their job appropriately, but safety is also important.

For example, a construction team is working on a scaffolding to renovate a building with new fixtures, which is not installed & erected properly, causing it to collapse leaving many people injured; some with even fatal injuries. After accident investigation & analysis, it became evident that the scaffolding locks were not properly done due to which it became unstable causing an accident. Besides scaffolding locks, there are many more parts of scaffolding that needs to be properly installed by professionals who knows how to safely install a scaffolding to prevent accidents.

Similarly, there are many other jobs, before which the site supervisor shall always make sure stable platforms or structures, like:

- Repairing a roof of a house requires assurance of stable roof and scaffolding to avoid slips or falls

- An electrician first needs a stable ladder to install an electrical fixture in the ceiling to avoid fall injuries

- A paint job can only be done properly, if the workers are provided with an appropriately erected scaffolding platform

- Cracked or Rusty standing platforms shall be replaced with appropriate risk-free platforms to prevent breakage which might result in falling objects like heavy tools causing head injuries in some cases

- A site supervisor shall always make sure that an appropriate material is used for bridging structures to avoid breakages or collapse, like in Chemical Industry, wooden planks shall never be used for bridging

Vehicle/Object Collisions:

Vehicle and Object Collisions often happen at workplaces like construction sites, port sites, engineering industries and few other industries which have influx of heavy machinery & equipment. They can result in severe damages to assets and can be fatal if relevant safety measures are not taken in to consideration.

Just in case a tower crane on a port site is moving a cargo container towards an ocean freighter to lodge the shipment, but it collides with a loaded cargo truck coming its way due to the inefficient signaling. The severity of damages depends on the speed of the truck and the weight of the container lifted by the tower crane and if we see hypothetically, this kind of accident can result in major collapses and heavy losses. A similar incident happened on a Turkish Port, this year in March, when a container ship while parking, collided with the Tower Cranes at Evyap Port resulting in crane collapses with heavy losses. These kinds of safety hazards can be avoided if;

- Crane operators have been through authentic crane operation safety training, so they can be well aware of accurate working procedures and associated risks before working on crane

- Surrounding area is clear of debris during vehicle maneuvering to avoid collision with a barrier, a person , a wall or an object

- Only trained and certified banksman are employed for ground operations to ensure efficient signaling which will reduce the risk of collision

- Forklift operators know how to safely operate a forklift accurately as per the job requirements

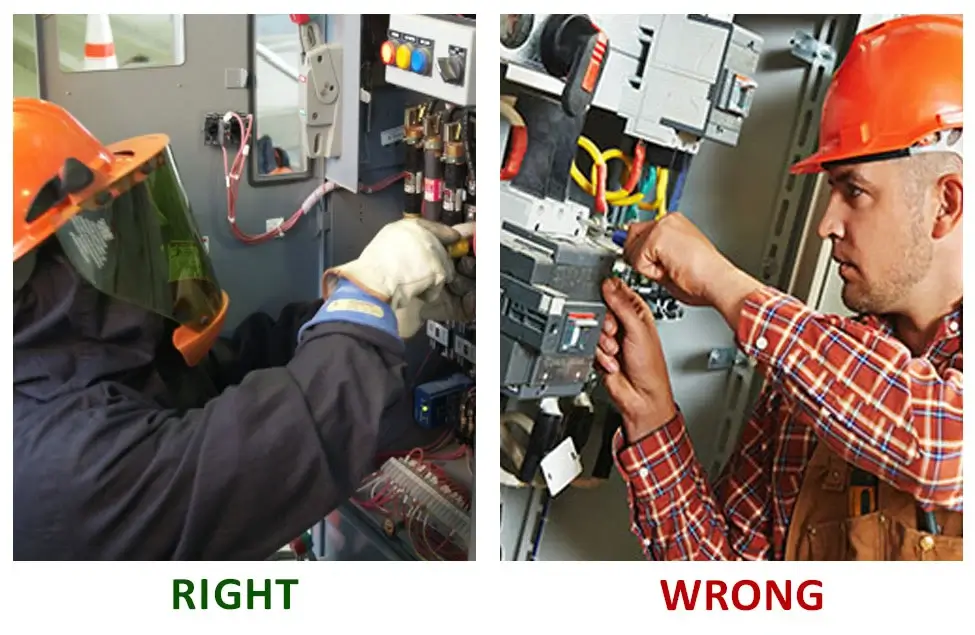

Electrical Hazards:

Electricity is itself a safety hazard, if appropriate safety precautions are not taken. It is the job of a worker and the supervisor to make sure accurate safety arrangements like insulated safety gloves, electrical shock proof shoes, insulated ladders and few other things to prevent accidents.

Large manufacturing units, multipurpose office buildings and even shopping malls have fully functional generator rooms to support their electricity requirements and always needs regular maintenance to keep them fit for operations. In due course of maintenance, if the workers have not taken electrical safety measures into account, they can be severely injured with a high voltage shock leading to death in most cases.

Likewise, there are many other incidents where keeping abreast of electrical safety standards can prevent accidents and losses, few of them are:

- An electrician working on main circuit of a house using insulated gloves and insulated tools to avoid shocks

- Implementing an appropriate electrical wiring plan using a high quality electrical wiring as per electrical safety best practices, will reduce the chances of short circuits

- Usage of high quality electrical appliances, but regularly checked for maintenance needs to avoid electrical failures

- Electrical extension cords shall not be overloaded to avoid overheating them which can result in electrical fires leading to catastrophic disasters

- Electrical switches shall be turned off when not in use to avoid short circuits, electrocution, and electrical sparks

- Frayed wiring shall always be properly insulated before being used to avoid electrocution and short circuits

Chemical Hazards:

We deal with many kinds of chemicals in our daily lives, soaps & cleaning agents being the most common ones, shall be properly washed away to avoid adverse effects. Likewise, in manufacturing industries, oil & gas industry, clinical & experimental laboratories and chemical processing & producing industries, workers are exposed to various chemicals on daily basis, and they shall be properly sanitized to avoid illness, injuries or even fatal accidents.

Each chemical has its own concentration upon which the intensity of its effect is based, like HCL, if in contact with the skin can cause severe chemical burns or if in case someone is dealing with a potassium chemical, shall handle it in dry environment as it is highly flammable when in contact with the moisture. PPE Gear is the key to protection from the adverse effects of chemical handling, but is just an initial step of chemical safety which is a detailed subject on how to control substances hazardous to health.

Here are few scenarios to help understand the importance of chemical safety:

- Potassium is used in glass production as mixing agent to form potassium carbonate which increases the transparency for effective clarity, but shall be handled wearing protective gear not just because its flammable, but is also highly corrosive to eyes, skin and mucous membranes

- Hydrogen Sulphide gas is a chemical compound which is highly toxic and causes breathing & other problems including apnea, convulsions, or irritability for people working in Oil & Gas industry, if they are not given proper H2S Safety Training

- Farmers who use fertilizers without any face shields and gloves have been reported to suffer from airborne illness like asthma or COPD (Chronic Obstructive Pulmonary Disease) or even cancer, due to the fertilizer dust emissions which are devastating for respiratory system

- Properly labeled and categorized chemical containers have proved to be safe for storage areas and ensures prevention from explosions & fire incidents

Besides above mentioned hazards, each industry has its own specific hazards also, which can be inspected and analyzed with various industry specific methodologies. Risk assessment is the most important initial step in the process of designing an effective health and safety framework, which helps in accurately identifying & understanding the risks of hazards to craft relevant safety strategies for hazard prevention.

Share the Knowledge

Find that interesting! Share it with the Friends.